Broan Elite EW48 Series 30-Inch Range Hood: Kitchen Ventilation for Colorado Homes

$978.00 Original price was: $978.00.$888.00Current price is: $888.00.

Custom Chimney Chase Covers: Premium Protection for Denver Chimneys

Last month, I replaced a rusted galvanized chase cover on a two-story home in Highlands Ranch. The homeowner had been dealing with water intrusion for years—stained drywall, musty odors, and deteriorating chimney structure—all caused by a failing $80 factory chase cover. We installed a custom 20-ounce copper chase cover, laser-cut to exact dimensions with properly soldered seams. The difference wasn’t just aesthetic—it was structural protection that will last 50+ years instead of 5.

Understanding Chimney Chase Covers

A chimney chase cover—also called a chimney pad or chase top—serves as the “roof” for prefabricated or chase-style chimneys. Unlike traditional masonry chimneys with clay flue tiles and cement crowns, factory-built chimneys feature metal or wood-framed chases that require a weathertight metal cover to prevent water damage, the leading cause of premature chimney failure in Denver’s climate.

The chase cover performs critical functions: it sheds water away from the chimney structure, protects the chase interior from moisture infiltration, seals penetrations around flue pipes and caps, and provides a finished appearance that complements your home’s exterior. When properly fabricated and installed, a quality chase cover can eliminate up to 90% of potential water-related chimney problems.

Material Options and Performance Characteristics

Premium Metal Selections

| Material | Gauge/Weight | Lifespan | Best Applications | Starting Price Range |

|---|---|---|---|---|

| Copper | 16 oz., 20 oz. | 50+ years | Upscale homes, architectural statements | $450-900 |

| Lead Coated Copper | 16 oz., 20 oz. | 40+ years | Historic restorations, traditional aesthetics | $500-950 |

| Freedom Gray (Zinc/Tin Coated Copper) | 16 oz., 20 oz. | 40+ years | Modern design, low-maintenance | $425-850 |

| Stainless Steel 304 2B | 24 gauge | 30-40 years | Contemporary homes, coastal climates | $350-700 |

Standard Metal Options

| Material | Gauge | Lifespan | Best Applications | Starting Price Range |

|---|---|---|---|---|

| Kynar Aluminum | 0.032″ | 25-35 years | Color-matched applications, lighter weight | $275-550 |

| Kynar Galvalume (Steel) | 24 gauge | 25-30 years | Budget-conscious quality, painted finishes | $250-500 |

| Galvalume Plus | 24 gauge | 20-30 years | Standard protection, good value | $225-475 |

| Galvanized Steel G90 | 24, 26 gauge | 15-25 years | Basic protection, entry-level | $200-425 |

| Bonderized Steel (Paint Grip) | 26 gauge | 15-20 years | Paint-ready surface, custom colors | $200-400 |

Pricing varies based on chase dimensions, material thickness, and fabrication complexity. These ranges reflect typical Denver-area installations for standard residential chimneys.

Material Selection Guide for Denver’s Climate

Denver’s unique environment—characterized by intense UV exposure, dramatic temperature swings, low humidity, and occasional severe weather—demands thoughtful material selection. Here’s what I recommend based on 15 years of local installations:

Copper: The Premium Standard

Copper remains the gold standard for chase covers in Denver. The material naturally weathers to a distinctive patina—progressing from bright penny copper to brown, then eventually developing the classic verdigris green over 15 to 20 years. This patina actually protects the underlying metal, extending service life beyond 50 years.

I installed a 16-ounce copper chase cover on a home in Cherry Creek in 2010. Fourteen years later, it exhibits a beautiful, even patina development and shows no signs of deterioration. The homeowner loves how the weathered copper complements their stone exterior—an aesthetic impossible to achieve with painted metals.

16 oz. vs. 20 oz. Copper: The heavier 20-ounce material provides additional rigidity for larger chase covers (over 40 inches square) and better handles snow loads during Denver’s occasional heavy storms. For standard residential applications under 36 inches, 16-ounce Costopper performs exceptionally well at a lower cost.

Freedom Gray: Modern Alternative to Traditional Copper

Freedom Gray—a zinc and tin coating over copper—offers the durability of copper with a contemporary gray finish that remains consistent in color. This material suits modern architectural styles popular in Stapleton, Lowry, and newer developments, where traditional copper patina doesn’t match design aesthetics.

The coating offers excellent corrosion resistance while retaining the structural benefits of the copper substrate. Unlike painted finishes that eventually fail, Freedom Gray’s metallic coating bonds permanently to the copper base.

Stainless Steel: Contemporary Durability

Type 304 stainless steel provides excellent corrosion resistance and maintains its bright metallic appearance indefinitely. The 2B finish offers a smooth, professional look that complements contemporary and industrial design elements.

I frequently specify stainless steel for modern mountain homes, where the bright metal echoes architectural details such as steel railings or metal roofing. The material handles temperature extremes well and resists oxidation that affects lesser metals in Denver’s intense sunlight.

Kynar Coatings: Color-Matched Solutions

Kynar-coated aluminum and galvalume offer factory-applied paint finishes in numerous colors, allowing chase covers to match existing trim, siding, or architectural elements. The Kynar fluoropolymer coating resists UV degradation significantly better than standard paints—critical for Denver’s 300+ days of annual sunshine.

I recently installed a brown Kynar aluminum chase cover on a log home in Evergreen. The color matched their existing brown metal roof perfectly, creating visual continuity across the home’s exterior. After three years, the finish shows no fading—a testament to Kynar’s UV stability.

Budget Options: When to Choose Galvanized or Galvalume

Galvanized and galvalume chase covers provide homeowners with adequate protection at a minimum cost. These materials work acceptably in Denver’s dry climate—moisture exposure is less constant than in humid regions, where they fail rapidly.

However, I’m candid with clients: galvanized covers typically last 15-20 years before requiring replacement, while copper or stainless steel installations are essentially permanent—the initial savings of $200-$300 become a recurring expense when replacement is necessary.

Design Features and Fabrication Quality

Laser-Cut Precision

Every chase cover is laser-cut to your exact chimney dimensions, ensuring a perfect fit without field modifications. This precision matters enormously—gaps of even 1/8 inch allow water infiltration that defeats the cover’s purpose. I’ve replaced dozens of poorly fitted covers where water channeled through gaps, causing thousands of dollars in structural damage.

The laser cutting process creates clean edges that facilitate proper seaming and soldering, producing watertight joints that are impossible to achieve with hand-sheared metal.

3.5-Inch Tall Sides with X-Bend

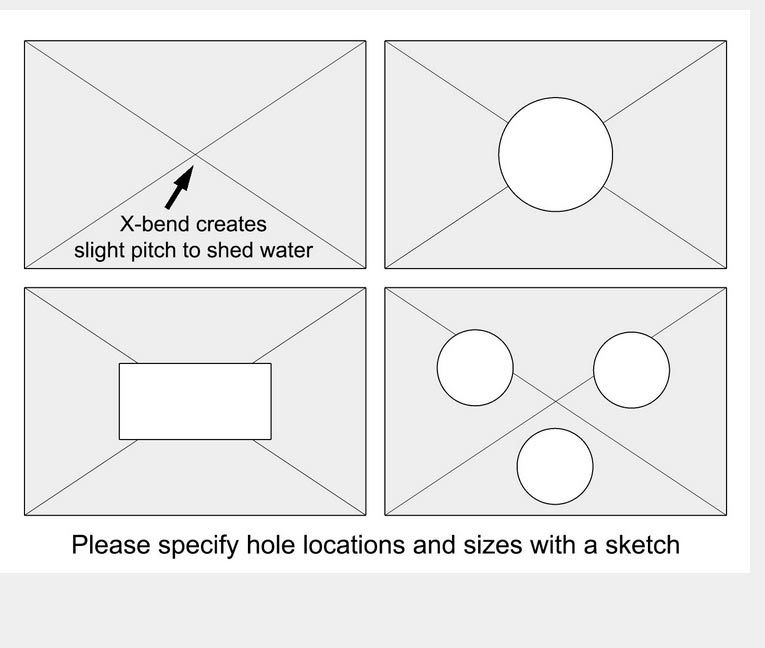

The standard 3.5-inch vertical sides, called the skirt, provide several functions. This height ensures adequate overlap with the chase walls for secure fastening and weather protection. The x-bend (a small fold in the metal) adds rigidity, preventing oil-canning (waviness) in the flat metal surfaces.

Denver’s wind conditions make this rigidity essential. I’ve seen thinner covers without proper bends flex and eventually tear at fastener points during sustained winds of 40+ mph, common along the Front Range.

Pipe Lock Seams for Large Covers

Chase covers exceeding single sheet dimensions require joining multiple pieces. The fabrication uses pipe lock seams—mechanically interlocked joints that create strong, weathertight connections. While visible upon close inspection, these seams don’t compromise performance or aesthetics from ground level.

Our Strong Recommendation: Copper, lead-coated copper, Freedom Gray, and stainless steel chase covers should be soldered after installation for maximum weather protection. The soldering process creates completely waterproof seams that withstand Denver’s freeze-thaw cycles and prevent capillary action, which draws moisture through mechanical seams.

I always include soldering in my installations of premium materials. The additional labor investment ($120-180 typically) provides insurance against the most common failure mode—seam leakage—and extends cover life by decades.

Installation Methods and Mounting Options

Side Mount Installation (Standard)

Side mount represents the most common and versatile installation method. Fasteners penetrate through the vertical skirt into the chase walls, creating a secure attachment that resists wind uplift while remaining easily accessible for service.

Fastening Options:

| Method | Best Applications | Advantages | Considerations |

|---|---|---|---|

| Stainless Steel Screws | Wood-framed chases | Easy installation, removable | Pre-drill to prevent splitting |

| Masonry Anchors | Brick/block chases | Strong hold, permanent | Requires a proper drill bit and technique |

| Tapcon Screws | Concrete/masonry | Excellent holding power | Must use the correct size for the material thickness |

| Construction Adhesive | Situations where fasteners show undesirably | Clean appearance, no penetrations | Permanent, not removable for service |

I typically use stainless steel screws spaced every 8 to 10 inches around the perimeter. This spacing provides adequate wind resistance—Denver’s building code requires fastening capable of withstanding 90 mph wind loads for our area.

Professional Installation Recommendation: Although the process appears straightforward, proper installation requires expertise in several critical details. Correct fastener spacing prevents wind damage. Proper sealant application around flue penetrations prevents leaks. Accurate alignment ensures water drains correctly. Minor errors in any of these areas compromise the effectiveness of the entire installation.

Our chase cover installation service includes the removal of the old cover, thorough cleaning of the chase walls, proper fastener selection and spacing, soldering of seams for premium materials, flashing and sealing around flue pipes, and a final inspection to verify a weathertight installation. The service type 80-i650 $$ $3,650, depending on the chase size and access investment, making it an investment that protects your $400-$900 chase

Dimensional Considerations and Custom Fabrication

Standard Residential Sizes

Most Denver-area prefabricated chimneys fall into common dimensional ranges:

| Chase Dimension Range | Typical Applications | Fabrication Notes |

|---|---|---|

| 18″ x 18″ to 24″ x 24″ | Single flue factory chimneys | Single sheet, no seams required |

| 26″ x 26″ to 36″ x 36″ | Standard two-story installations | Single sheet, straightforward fabrication |

| 38″ x 38″ to 48″ x 48″ | Large homes, multiple flues | May require seamed construction |

| 50″ x 50″ and larger | Custom homes, commercial | Always requires pipe lock seams |

Measuring for Perfect Fit

Accurate measurement is critical—I’ve seen homeowners order covers based on interior chase dimensions when exterior dimensions are required, resulting in unusable products. Here’s the proper measurement process:

Step 1: Measure the exterior dimensions of the chase at the top, where the cover will be positioned. For rectangular chases, measure both length and width.

Step 2: Note the locations and sizes of all flue pipe penetrations. Include distances from chase edges to the center of the pipes.

Step 3: Identify any unusual features—such as FF-center pipes, angled chases, or non-standard configurations—that require custom fabrication.

Step 4: Photograph the existing chase cover from multiple angles, showing overall configuration and pipe arrangements.

If you’re uncertain about any measurements, I strongly recommend a professional measurement service. We provide complimentary measurement with installation booking—eliminating the expensive possibility of ordering incorrectly sized covers.

Custom Designs and Non-Standard Applications

Beyond standard rectangular chase covers, custom fabrication addresses unique situations I regularly encounter in Denver’s diverse housing stock:

Angled Chases: Mountain homes and A-frame designs often feature sloped chases that require covers with varying skirt heights to maintain proper drainage.

Multiple Flue Configurations: Homes with multiple fireplaces or heating appliances may have 3-4 flue pipes penetrating a single chase, requiring precise placement of the pipes in the cover.

Architectural Details: Custom edge profiles, decorative elements, or specific color matching for landmark or historic properties.

Oversized Commercial Applications: Apartment buildings, condominiums, or commercial structures with large factory-built chimneys.

Contact us directly for custom fabrication pricing. We collaborate with the manufacturer to develop specifications that meet your exact requirements while maintaining structural integrity and weather protection.

Common Chase Cover Failure Modes in Denver

Understanding why chase covers fail helps appreciate the value of quality materials and installation:

Rust and Corrosion

Standard galvanized steel covers typically last 10-15 years before rust perforation occurs. Denver’s dry climate actually extends this timeline compared to humid regions—moisture drives corrosion, and we have relatively little of it. However, UV exposure and temperature cycling eventually degrade the galvanized coating, exposing bare steel to oxidation.

I replaced a 12-year-old galvanized cover last week in Centennial. Multiple rust-through holes had developed, allowing water to pour into the chase during rain. The interior framing showed extensive water damage, requiring $2,800 in structural repairs in addition to the cost of cover replacement. A copper cover installed initially would have avoided this entirely.

Seam Failure

Factory-fabricated covers often feature inadequate seaming—simple overlaps with exposed fasteners or thin sealant beads. Thermal expansion and contraction cycles gradually work these seams open. Water infiltration usually follows, going unnoticed until interior damage becomes apparent.

Properly soldered seams on copper and stainless steel covers eliminate this failure mode. The solder creates a metallurgical bond that is far stronger and more durable than mechanical fastening or sealants.

Wind Damage

Inadequate fastening allows wind to lift cover edges during sustained high winds. Once lifting begins, progressive damage occurs—fasteners enlarge holes, metal fatigues, and eventually the entire cover can tear free.

Denver’s wind environment demands respect. We regularly see sustained winds of 40-50 mph during spring chinook events, with gusts exceeding 70 mph. Proper fastener spacing and adequate edge engagement prevent these failures.

Improper Drainage

Chase covers must slope away from flue penetrations toward the edges, allowing water to drain off rather than pooling. Flat or improperly sloped covers accumulate water, accelerating corrosion and eventually developing leaks at seams or penetrations.

The 3.5-inch skirt height, combined with a proper slope, creates positive drainage. Water exits the cover completely rather than running down chase walls where it can find penetration points into the structure.

Installation Process and Timeline

Our typical chase cover installation in Denver follows this sequence:

Day 1 – Site Assessment and Measurement (if not previously completed):

- Access the roof safely using appropriate fall protection

- Remove existing cover for accurate measurement if necessary

- Photograph the chase configuration and document all penetrations

- Verify the structural condition of the chase, requiring any repairs, before cover installation

- Place an order for a custom-fabricated cover

Manufacturing Lead Time: 2-4 weeks, depending on material selection and current production schedule

Day 2 – Installation:

- Access the roof and stage material. Remove the old chase cover and dispose of it properly

- Clean chase top, removing old sealant and debris

- Inspect the chase structure, addressing any deterioration

- Position the new cover, verifying proper fit

- Install fasteners per the manufacturer’s specifications and the Denver building code

- Solder seams for copper, stainless, or Freedom Gray installations

- Seal around flue pipe penetrations with high-temperature sealant

- Final inspection and cleanup

Most installations are complete in 3-4 hours of on-site work. Complex situations—such as multiple flues, difficult roof access, or structural repairs—may require additional time.

Maintenance and Long-Term Performance

Quality chase covers require minimal maintenance but benefit from periodic inspection:

Annual Inspection: Conduct a visual check for any damage, fastener looseness, or sealant deterioration around flue pipes. We include this in our standard chimney inspection service starting at $199.

Cleaning: Copper and Freedom Gray covers benefit from occasional cleaning, if desired, although it’s not required for optimal performance—stainless steel maintains its appearance with simple soap and water washing.

Sealant Renewal: High-temperature sealant around flue pipe penetrations typically lasts 10-15 years before requiring renewal. This simple maintenance prevents 90% of potential leak problems.

Fastener Inspection: After severe wind events, verify fasteners remain secure. Loose screws can be retightened, preventing progressive damage.

Properly installed premium chase covers should provide 30-50 years of trouble-free service with these minimal maintenance requirements—a stark contrast to the 10-15 year replacement cycle for economy covers.

Investment Analysis: Premium vs. Economy Materials

The cost difference between materials creates decision points for homeowners. Here’s how I frame the analysis:

20-Year Cost Comparison

| Scenario | IniCost Cost | Maintenance | Replacements | Total 20-Year Cost |

|---|---|---|---|---|

| Economy Galvanized (replaced twice) | $425 | $0 | $850 (2 @ $425) | $1,275 |

| Mid-Grade Galvalume (replaced once) | $500 | $0 | $500 (1 @ $500) | $1,000 |

| Premium Copper (no replacement) | $750 | $0 | $0 | $750 |

| Premium Stainless (no replacement) | $650 | $0 | $0 | $650 |

Assumes professional installation costs of $450 each time, included in all scenarios

The analysis becomes more dramatic over 30-40 years, the typical duration of homeownership. Premium materials actually cost less than repeated economy replacements while eliminating the hassle and disruption of multiple installations.

The Hidden Cost Factor

These calculations omit potential water damage costs from chase cover failure. I’ve documented repair costs ranging from $1,500 for minor drywall replacement to $8,500 for structural framing repairs when cover failures went unnoticed, allowing years of water infiltration.

Premium materials dramatically reduce this risk. A properly installed copper or stainless steel chase cover essentially eliminates water intrusion as a concern—the cover won’t fail during your homeownership period.

Why Choose Professional Installation

While some homeowners consider DIY chase cover installation, several factors favor professional service:

Safety: Roof work presents serious fall hazards. We maintain comprehensive liability insurance, utilize proper fall protection, and adhere to OSHA-compliant safety protocols.

Measurement Accuracy: Incorrect measurements result in unusable covers—a $400-900 mistake. Professional measurement ensures first-time accuracy.

Soldering Expertise: Proper soldering requires specific tools, materials, and techniques. Poor soldering actually reduces weather protection versus mechanical seams alone.

Fastening Knowledge: The selection and spacing of fasteners vary depending on the construction, material thickness, and wind exposure. Inadequate fastening causes premature failure.

Code Compliance: Denver’s building department may require permits for the replacement of chase covers on specific properties. We handle all permitting and inspection requirements.

Warranty Protection: Many cover manufacturers require professional installation for warranty validation. DIY installation may void coverage.

Our installation service includes all these elements plus disposal of old covers, cleanup, and a service guarantee. The peace of mind that comes with knowing your expensive chase cover is installed correctly justifies the professional service investment for most homeowners.

Getting Started with Your Chase Cover Replacement

If you’ve noticed rust on your existing chase cover, water stains on interior walls near the chimney, visible gaps or holes in the current cover, or if your galvanized cover is approaching 15 years old, it’s time to consider replacement before water damage occurs.

Contact us at (720) 207-9232 to schedule a chase cover evaluation. We’ll inspect your current cover and chase structure, measure fabrication, discuss material options and pricing, recommend appropriate solutions for your home and budget, and provide a detailed estimate that includes the installation, at 12894 E VilDr. Serving Denver metro homeowners with professional chimney services, including chase cover fabrication and installation.

Protect your chimney investment with a high-quality chase cover that will outlast your homeownership, providing decades of reliable weather protection and enhancing your home’s exterior appearance with premium materials and professional craftsmanship.

Made in the USA – Supporting American manufacturing while ensuring quality materials and fabrication standards that meet Denver’s demanding climate requirements.